+86 13600513715

+86 13600513715

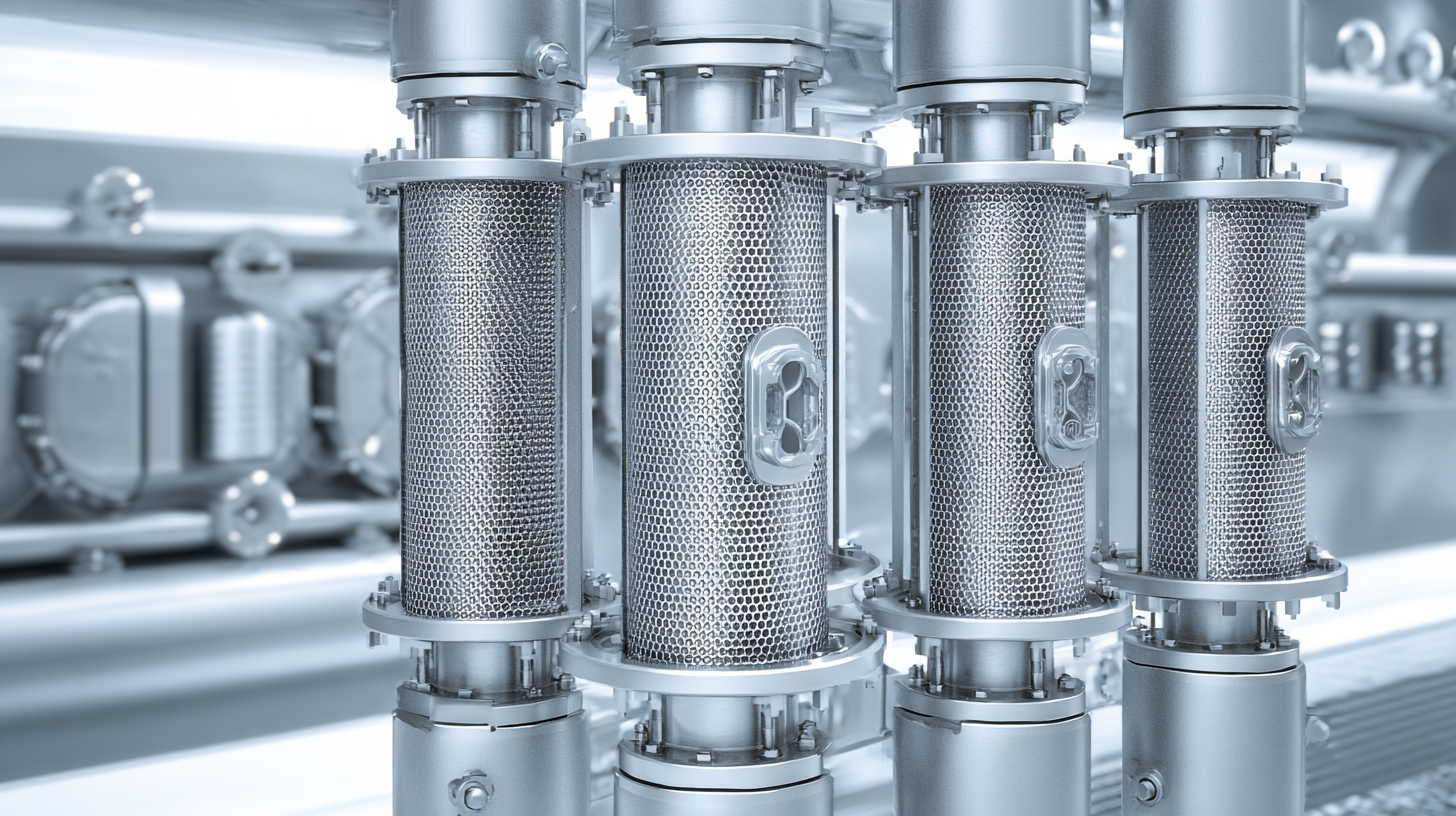

In the realm of industrial applications, effective separation processes are crucial for optimizing efficiency and reducing operational costs. One of the pivotal technologies employed in these processes is Plate and Tube Settlers, which play a significant role in enhancing the sedimentation capabilities of water and wastewater treatment systems. However, despite their numerous advantages, these systems often face common challenges that can hinder their performance and reliability. This blog aims to address these challenges by exploring best practices and solutions for the effective implementation of Plate and Tube Settlers. By examining potential issues such as scaling, improper design, and maintenance concerns, we will provide valuable insights and actionable strategies to help industries overcome these obstacles, thus ensuring the optimal functionality of their sedimentation systems. Join us as we delve into the intricacies of Plate and Tube Settlers and discover how to maximize their effectiveness in various industrial applications.

Efficient settling solutions are crucial in industrial water treatment, as they significantly enhance the separation process and reduce the volume of sludge. According to the Water Environment Federation, proper settling techniques can improve the removal of suspended solids by up to 90%, directly impacting both the operational costs and environmental compliance of water treatment facilities. This efficiency is paramount as industrial activities produce a substantial amount of wastewater, with the EPA estimating that industrial discharges account for about 20% of the total wastewater released annually in the U.S.

The implementation of best plate and tube settlers can optimize this process by maximizing surface area and promoting laminar flow, which leads to more effective particle settling. Industry studies suggest that using inclined plate settlers can achieve overflow rates ranging from 5-10 times higher than conventional clarifiers. This not only enhances sedimentation rates but also minimizes footprint requirements in facilities, allowing industries to conserve space while maintaining high processing capabilities. By investing in advanced settling technologies, companies can ensure regulatory compliance while improving overall operational efficiency and sustainability in their water treatment practices.

| Parameter | Value | Importance | Common Challenges |

|---|---|---|---|

| Settling Rate | 1.5 m/h | Critical for removal of suspended solids | Fluctuations in flow rate |

| Operating Temperature | 20°C - 30°C | Affects polymer performance | Temperature fluctuations |

| Hydraulic Retention Time | 2 hours | Essential for effective settling | Variability in inflow |

| Settler Efficiency | 85% | Determines overall process effectiveness | Clogging of settlers |

| Maintenance Frequency | Monthly | Prevents operational issues | Overlooked maintenance schedules |

In industrial applications, choosing the right plate and tube settlers is crucial for enhancing separation efficiency and reducing costs. High-quality settlers incorporate key features that significantly contribute to optimal performance. For instance, innovative designs with larger surface areas can improve sedimentation rates, as supported by a report from the International Water Association, which states that properly designed settlers can achieve up to 90% removal efficiency of suspended solids.

When selecting settlers, consider the material and configuration. High-density polyethylene (HDPE) and polypropylene are commonly recommended for their durability and resistance to corrosion. Moreover, tapered tube designs have been shown to improve flow dynamics, minimizing dead zones where sediment can accumulate, thereby optimizing overall system effectiveness. According to a recent industry analysis, systems employing well-structured plate and tube settlers have reported up to 30% increases in treatment capacity.

**Tip:** Regular maintenance is essential to ensure your settlers operate at peak efficiency. Inspect for any signs of wear or blockage, and clean surfaces to prevent the buildup of sludge.

**Tip:** Monitor the influent characteristics regularly. Understanding the particle size distribution can aid in adjusting the settler design and configuration for better performance, ensuring that the system adapts to changing operational demands.

In industrial applications, the efficiency of plate and tube settlers is crucial for optimizing solid-liquid separation processes. Performance metrics play a significant role in evaluating how well these settlers perform in real-world scenarios. Key metrics include settling velocity, surface loading rate, and effluent clarity. By analyzing these factors, operators can identify bottlenecks and enhance the design and operation of settlers.

Settling velocity, for example, directly impacts the overall efficiency of a settling system. Higher settling velocities indicate that solids are being effectively removed from the liquid, minimizing the risk of re-suspension. Additionally, surface loading rates help determine how much flow the settlers can handle without compromising performance. Regular monitoring and assessment of these metrics allow facilities to adapt to changing conditions, ultimately leading to improved process reliability and lower operational costs.

In recent years, the use of plate and tube settlers has gained traction in various industrial applications due to their efficiency in enhancing sedimentation processes. A notable case study examines a wastewater treatment plant in California, where the implementation of advanced plate settlers reduced the space required for sedimentation by 40%. According to a 2022 report by the American Water Works Association, facilities that adopt these settlers can increase the settling rate by up to 50%, leading to significantly lower operational costs and improved treatment efficiency.

Another compelling success story comes from a mining operation in Australia. The introduction of tube settlers enabled the facility to handle increased flows during peak operations, which would have previously overwhelmed traditional settling tanks. The operational metrics revealed a remarkable 30% reduction in sludge volume, allowing for more effective resource recovery. An industry analysis published by the International Journal of Mineral Processing highlighted that such innovations could result in savings of up to $500,000 annually, emphasizing the financial benefits of incorporating best practices in sedimentation processes across different sectors.

The manufacturing of plate and tube settlers is evolving rapidly, driven by innovations in materials and technology. One notable trend is the increased use of lightweight, high-strength polymers that enhance durability and reduce installation costs. According to a report by Research and Markets, the global plate settler market is projected to grow at a CAGR of 6.2% from 2022 to 2027, largely fueled by the demand for more efficient wastewater treatment solutions. Manufacturers are also focusing on improving the surface area of settlers to enhance sedimentation rates and reduce settling times, leading to higher operational efficiencies.

Moreover, digital technologies such as IoT and AI are beginning to play a significant role in the monitoring and maintenance of plate and tube settlers. Predictive maintenance tools can now analyze real-time data from sedimentation processes, helping to optimize performance and prevent downtime. A recent study showed that integrating AI into settling systems can improve efficiency by over 15%, allowing industrial applications to better manage their resources while meeting stricter environmental standards. As these trends continue to develop, the plate and tube settler industry is set to play a crucial role in modern industrial applications, addressing both operational challenges and sustainability goals.