+86 13600513715

+86 13600513715

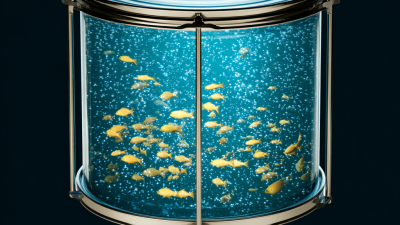

Choosing the right drum filter for your aquaculture needs is crucial for maintaining a healthy and efficient aquatic environment. A Drum Filter Aquaculture system serves as a vital component in managing water quality by effectively removing solid waste and debris from the water. As the aquaculture industry continues to grow, the demand for reliable filtration systems has never been higher.

Choosing the right drum filter for your aquaculture needs is crucial for maintaining a healthy and efficient aquatic environment. A Drum Filter Aquaculture system serves as a vital component in managing water quality by effectively removing solid waste and debris from the water. As the aquaculture industry continues to grow, the demand for reliable filtration systems has never been higher.

With various types of drum filters available, selecting the appropriate one can be overwhelming. Factors such as the specific requirements of your aquaculture setup, the type of species being cultivated, and the overall scale of your operation all play a significant role in this decision-making process. This guide will provide you with essential insights and practical tips to help you navigate through the options and ultimately choose the best drum filter to optimize your aquaculture system's performance.

Drum filters play a crucial role in maintaining water quality within aquaculture systems. They are designed to remove solid waste and particulate matter from the water, which is essential for ensuring the health and growth of fish and other aquatic organisms. According to a report by the Aquaculture Research Institute, effective filtration can reduce ammonia levels by up to 80%, thus mitigating the risk of harmful conditions for aquatic life. This is particularly important as poor water quality can lead to stress and disease outbreaks, which can severely impact yield and profit.

When selecting the right drum filter, consider several factors such as flow rate, mesh size, and the specific needs of your aquaculture operation. A common tip is to choose a filter with a mesh size appropriate to the species being cultivated; for instance, smaller mesh sizes are suitable for delicate fry, while larger ones can suffice for adult fish. Additionally, consulting with manufacturers and industry experts can provide insights into the most efficient models that fit your operational scale and budget.

Another tip is to regularly monitor the performance of your drum filter to ensure it is functioning optimally. Many systems come equipped with sensors that alert you to any malfunctions, enabling quick maintenance which can prevent costly downtime. Keeping track of maintenance schedules can enhance the longevity of the filter and maintain water quality, supporting the productivity of your aquaculture venture.

When selecting a drum filter for your aquaculture system, there are several key parameters to consider. First, assess the flow rate of your system. A drum filter's capacity should match or exceed the water flow, ensuring efficient filtration without overwhelming the unit. Look at the surface area of the filter mesh as well; a larger surface area allows greater debris capture, which can improve water clarity and reduce maintenance frequency.

Tips: Always check the specifications for the filter media. Different mesh sizes can affect the performance and suitability of the filter for specific types of aquaculture. For instance, if you are raising smaller fish, a finer mesh will be essential to prevent fry from being sucked into the filter.

Another important factor is the maintenance requirements of the drum filter. Automated cleaning systems can save time and labor, but consider the costs associated with more complex models. Regular maintenance is important to ensure long-term efficiency, so select a filter that suits your operational capacity while still meeting your aquaculture needs.

When selecting the ideal drum filter for aquaculture applications, understanding the comparative analysis of different drum filter technologies is crucial. Drum filters vary significantly in design and functionality, each offering distinct advantages depending on the specific requirements of the aquaculture system. For instance, mechanical drum filters provide efficient solid separation and are ideal for systems requiring high flow rates. They utilize a rotating mesh or screen, which captures particulates as water passes through, ensuring consistent water clarity and quality.

Another consideration is the choice between automatic and manual cleaning systems. Automatic drum filters, equipped with self-cleaning mechanisms, reduce labor costs and ensure continuous operation, making them suitable for large-scale aquaculture farms. In contrast, manual cleaning systems might be more cost-effective for smaller operations but require more frequent maintenance. Moreover, technologies such as hybrid drum filters combine both mechanical and biological filtration, offering enhanced versatility and improved water quality by targeting differing waste types. Evaluating these varying technologies allows aquaculture operators to make informed choices that align with their specific operational needs.

When selecting the right drum filter for aquaculture applications, evaluating flow rates and filtration efficiency is paramount. According to a report by the Global Aquaculture Alliance, maintaining optimal water quality is crucial for fish health, and a significant aspect of this is effective particulate removal. Drum filters typically offer varying flow rates—ranging from 10 to 30 cubic meters per hour—suitable for different scales of aquaculture operations. For instance, a smaller farm may find a filter with a flow rate of 10 m³/h sufficient, while larger facilities may require models exceeding 25 m³/h to manage waste effectively.

Filtration efficiency is also critical; a well-designed drum filter can remove particles as small as 50 microns. The Aquaculture Research Institute highlights that achieving a high level of filtration not only improves water quality but also reduces the overall operational costs by minimizing the need for water changes and chemical treatments. Therefore, when assessing drum filters, it’s essential to match the filtration efficiency with your specific aquaculture setup, ensuring it aligns with both the species being cultivated and the environmental conditions of the system in use. This targeted approach helps in maintaining a balanced ecosystem, promoting healthier aquatic life.

| Filter Model | Flow Rate (GPM) | Filtration Efficiency (%) | Suitable Aquaculture Type | Dimensions (inches) |

|---|---|---|---|---|

| Model A | 50 | 90 | Tilapia | 24 x 36 |

| Model B | 75 | 85 | Shrimp | 30 x 40 |

| Model C | 100 | 92 | Salmon | 36 x 48 |

| Model D | 65 | 80 | Catfish | 28 x 38 |

When evaluating drum filters for aquaculture operations, a comprehensive cost-benefit assessment is vital. Drum filters have gained traction due to their efficiency in removing particulate matter from water, which is critical in maintaining optimal water quality. According to a report by the Aquaculture Technology Consortium, proper filtration can enhance growth rates by up to 20% in fish farming environments. The initial investment in a drum filter system typically ranges from $5,000 to $15,000, depending on the scale and specific needs of the farm. This upfront cost must be weighed against potential increases in productivity and fish biomass.

In addition to the initial costs, ongoing operational expenses should be considered. Maintenance costs for drum filters are generally lower than for traditional systems, with reported savings of 30-50% on labor and upkeep. Further, a study published in the Journal of Aquaculture Resource Management indicates that using drum filters can reduce water usage by nearly 40%, translating into significant savings on water treatment and supply in the long run. Thus, aquaculture operators can achieve a favorable return on investment when properly assessing the total cost versus the operational efficiency and productivity improvements that drum filters can provide.