+86 13600513715

+86 13600513715

In the realm of wastewater treatment, the process of Mechanical Sludge Dewatering has emerged as a crucial step in enhancing efficiency and sustainability. According to Dr. Emily Carter, a leading expert in environmental engineering, "Effective Mechanical Sludge Dewatering is essential not only for reducing operational costs but also for minimizing the environmental impact of wastewater treatment facilities." This highlights the growing recognition of dewatering processes as integral to optimizing resource management in the industry.

As technology advances, understanding the intricacies of Mechanical Sludge Dewatering becomes more paramount for engineers and operators alike. The ability to efficiently separate water from sludge not only aids in reducing the volume of waste that requires processing but also facilitates the recovery of valuable materials. With increasing regulatory pressures and public focus on environmental stewardship, adopting best practices in this area cannot be overstated.

This comprehensive guide aims to equip professionals with the knowledge and tools necessary for effective Mechanical Sludge Dewatering. By exploring the latest techniques, technologies, and strategies, readers will gain valuable insights into optimizing their processes to achieve both economic and ecological benefits.

Mechanical sludge, often a byproduct of wastewater treatment processes, consists of solids that need effective management to minimize environmental impact. Understanding its composition and characteristics is crucial for developing efficient dewatering strategies. Mechanical sludge typically contains a mixture of organic and inorganic materials, which, when not handled correctly, can lead to issues such as overflow and increased disposal costs. The dewatering process not only reduces the volume of sludge but also improves its handling properties, making further processing or disposal much easier.

Dewatering mechanical sludge is essential for several reasons. Firstly, it significantly lowers transportation costs by decreasing the weight and volume of the waste. Secondly, effective dewatering enhances the thermal and biological stability of sludge, which is crucial for safe land application and minimizes odors. Different dewatering methods, including centrifugation, belt filter presses, and vacuum filtration, can be employed based on the specific characteristics of the sludge and the desired end product. Understanding these factors enables facilities to implement the most suitable dewatering technology, thus ensuring environmental protection and regulatory compliance while optimizing operational efficiency.

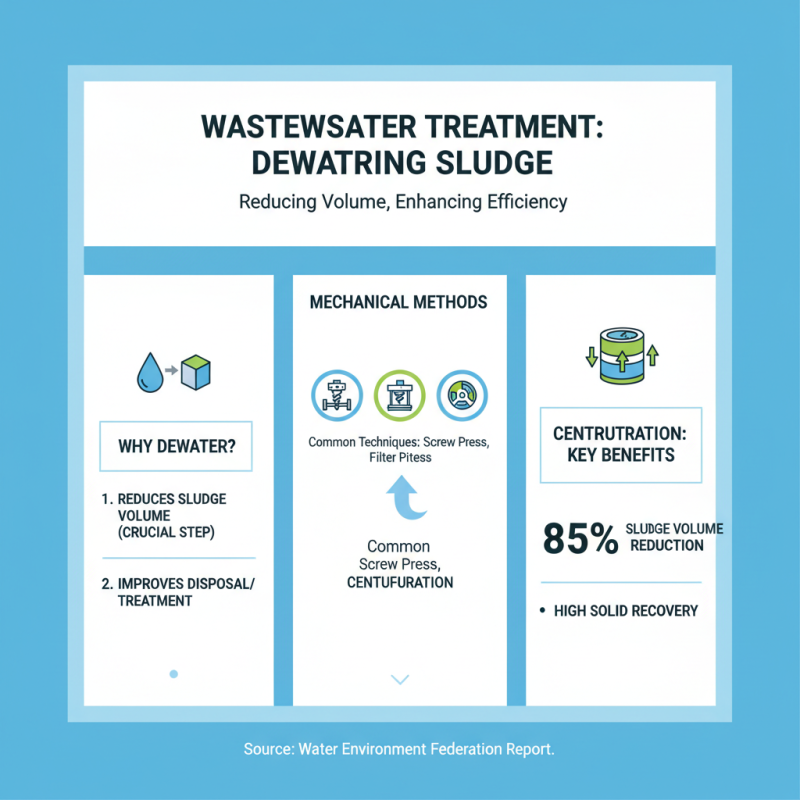

Dewatering mechanical sludge is a crucial step in wastewater treatment processes, significantly reducing the volume of sludge and enhancing the efficiency of disposal and treatment methods. Among the common methods employed, centrifugation stands out due to its ability to achieve high solid recovery rates. According to a report by the Water Environment Federation, centrifuges can reduce sludge volume by approximately 85%, making them one of the most effective options for large-scale facilities.

Another widely used technique is belt filter pressing, known for its versatility and relatively low energy consumption. A study published in the Journal of Environmental Engineering indicates that belt filter presses can achieve solid content levels between 18% and 30%, depending on the characteristics of the sludge and operational parameters. This method is particularly beneficial for municipal wastewater treatment plants where space and operational costs are significant considerations.

Lastly, drying beds provide a cost-effective alternative, especially in areas where land is available. Although they require more time and are less efficient in volume reduction compared to mechanical methods, they are popular due to their simplicity and low maintenance requirements. According to the International Water Association, drying beds can reduce sludge moisture content by up to 70%, making them a viable option for small facilities or as a preliminary treatment step.

Dewatering mechanical sludge is a critical process in wastewater treatment, and several key factors influence its effectiveness. First, the characteristics of the sludge itself play a significant role; parameters such as particle size, chemical composition, and solids concentration can determine how easily water can be removed. For instance, thickened sludge generally dewaters better than more fluid mixtures due to the decreased water-to-solid ratio.

Additionally, the dewatering method employed significantly impacts the process. Common techniques include centrifugation, belt filtration, and vacuum filtration, each with unique operational mechanisms and efficiencies. The choice of method often depends on the specific requirements of the sludge and the desired dryness level. Conditioning agents, such as polymers, can also enhance dewatering by promoting flocculation, helping to agglomerate the solids and facilitating easier water removal. Understanding the interplay between these factors is essential for optimizing the dewatering process in any mechanical sludge management operation.

Optimizing dewatering efficiency is crucial for managing mechanical sludge in various industries, from wastewater treatment to construction. One of the best practices to enhance this process is selecting the appropriate dewatering method based on the sludge characteristics. Techniques such as centrifugation, belt filter presses, or vacuum filtration can be evaluated according to the moisture content and the solid particle size distribution. Conducting thorough tests on sludge samples before implementation ensures a tailored approach that maximizes water removal.

Another essential aspect is the conditioning of sludge to improve its dewaterability. Adding coagulants or flocculants can significantly enhance the separation of solids from liquids. Chemicals such as polyacrylamide or ferric chloride promote floc formation, which leads to better performance during mechanical dewatering processes. Additionally, maintaining optimal pH levels and monitoring environmental conditions contribute to achieving higher output and reduced operational costs. Regular maintenance and calibration of dewatering equipment also play a vital role in sustaining efficiency levels throughout the sludge management process.

Dewatering mechanical sludge is a critical process in wastewater management, yet operators often face several common issues that can impede efficiency. One prevalent challenge is the presence of excessive polymers or chemical additives that can lead to poor dewatering performance. According to the Water Environment Federation, optimizing polymer dosage is essential, as overuse can result in increased filtrate turbidity and unwanted sludge viscosity, sometimes leading to a 15-20% drop in dewatering rates. Regular monitoring and adjustments based on specific sludge types can significantly enhance performance.

Another common issue arises from equipment malfunctions, particularly with centrifuges and belt presses. A report by the Environmental Protection Agency highlights that up to 30% of operational downtime in dewatering facilities can be attributed to mechanical failures. Implementing a proactive maintenance schedule can mitigate these disruptions. Additionally, ensuring that operators are well-trained can further reduce human error, which is a significant factor in many operational failures. By addressing these issues through systematic troubleshooting and regular maintenance, facilities can improve their dewatering efficiency and reduce operational costs.