+86 13600513715

+86 13600513715

Mechanical Sludge Dewatering plays a crucial role in waste management. With proper techniques, facilities can enhance their operational efficiency. According to the Water Environment Federation, effective dewatering can reduce sludge volume by up to 90%. This statistic highlights the importance of efficient sludge processing.

Many plants still struggle with outdated dewatering methods. These methods can lead to increased costs and environmental impacts. A 2021 report by the U.S. Environmental Protection Agency found that improper sludge management leads to significant financial losses. Facilities need to rethink their strategies to avoid these pitfalls.

Adopting modern technologies can transform mechanical sludge dewatering. Innovations like centrifuges and belt presses are becoming prevalent. These advancements not only reduce volume but also improve the quality of treated sludge. However, investing in new technologies requires careful consideration of costs and maintenance.

Mechanical sludge is a byproduct of wastewater treatment processes. It primarily consists of organic and inorganic materials. This mixture also contains microorganisms and other contaminants. Understanding its composition is key to effective management. Properties like moisture content and density impact how sludge is handled.

The physical characteristics of mechanical sludge vary. Some sludge can be thick and viscous, while others are more fluid. These differences often complicate dewatering efforts. If not managed properly, sludge can produce odors and attract pests. Efforts to improve the dewatering process must consider these variables.

Effective dewatering aims to reduce the volume of sludge. It also minimizes environmental impact. Common methods include centrifugation and mechanical pressing. However, these techniques might not be suitable for all types. Understanding the characteristics of the sludge is crucial for choosing the right method. A mismatch can lead to inefficiencies and increased costs. Regular assessments of sludge composition may improve practices and outcomes.

Dewatering mechanical sludge plays a crucial role in waste management operations. Effective dewatering reduces the volume of sludge, which is important for cost management. According to the Water Environment Federation, dewatering can lower transportation costs by up to 50%. This reduction is significant for facilities dealing with large volumes of waste.

Proper dewatering techniques can also lead to improved resource recovery. Many of the solids extracted during this process can be repurposed or treated further. Reports indicate that facilities that embrace innovative dewatering methods can achieve a 30% increase in biogas production. This is a valuable byproduct that can be utilized for energy generation.

However, challenges persist. Many plants struggle with the adequacy of their dewatering technology. Inadequate equipment leads to higher moisture content in the sludge, making disposal cumbersome. Improving technology and training staff can help address these gaps. Investing in better systems may require upfront costs, but over time, the return on investment becomes clear.

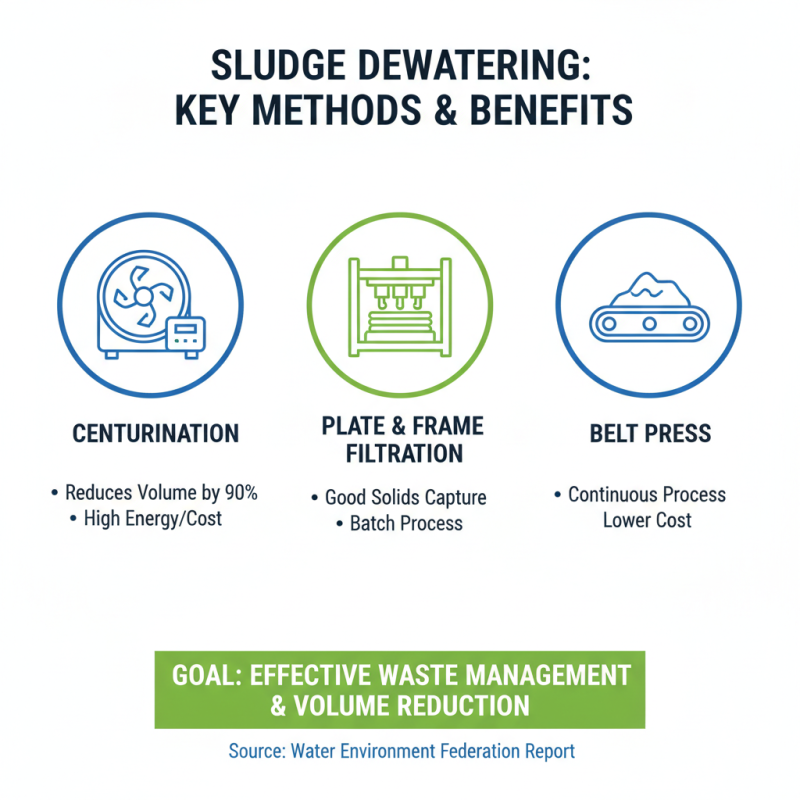

Dewatering mechanical sludge is crucial for effective waste management. Various techniques exist, each with unique benefits and drawbacks. The most common methods include centrifugation, plate and frame filtration, and belt presses. A report from the Water Environment Federation indicates that centrifugation can reduce sludge volume by up to 90%. However, it requires substantial energy and operational costs.

Belt presses are simpler and often more economical. They apply pressure to dewater sludge between two belts. According to the same report, belt presses can achieve 15% to 20% solids in the cake but may need more space and time. Despite their lower operational costs, they may not be as efficient for fine solids, leading to potential losses.

Plate and frame filters provide high dewatering rates but can be labor-intensive and require regular maintenance. Their performance often fluctuates based on the feed sludge characteristics. The inconsistency can lead to frustration, especially if operators lack sufficient training. This suggests a need for ongoing education in choosing the right dewatering method. Each option has trade-offs, and careful consideration of sludge characteristics is essential.

Effective dewatering of mechanical sludge significantly impacts waste management. According to a report by the Water Environment Federation, proper dewatering can reduce sludge volume by up to 90%. This reduction leads to lower transportation and disposal costs. When waste facilities operate efficiently, they save money, resources, and time.

Dewatering not only decreases waste volume but also enhances the quality of the remaining solid material. Facilities often face challenges in achieving optimal dryness levels. A common benchmark suggests achieving a cake with at least 20% solids. However, many plants struggle to reach this standard consistently. The costs associated with inadequate dewatering can be staggering, adding unnecessary financial pressure on waste management budgets.

Moreover, the environmental benefits of effective dewatering are profound. Reduced sludge volume means less landfill space is required. A study from the Environmental Protection Agency estimates that landfilling costs can rise by 30% if sludge is not dewatered properly. This cost can deter facilities from investing in better dewatering technologies. Ultimately, there is much room for improvement in this area, and facilities must address these gaps.

This chart illustrates the effects of effective dewatering on both the volume reduction of mechanical sludge and the associated disposal costs. As the percentage of solid content in the sludge increases, the volume significantly decreases, leading to lower disposal costs.

Dewatering mechanical sludge is crucial for effective waste management. To gauge the success of this process, key performance indicators (KPIs) are essential. These metrics provide a clear view of how well the dewatering system is performing in real time.

Moisture content is a primary KPI. Lower moisture levels indicate more efficient dewatering. Tracking this helps in adjusting processes as needed. Another critical measure is the cake solids concentration. A higher concentration reflects improved efficiency. However, achieving high solids often requires a balance. Excessive pressure can lead to equipment stress and performance decay.

Flow rate is also vital. It shows how much sludge is processed over time. A consistent flow rate implies a stable operation. Variability can highlight operational bottlenecks, but it often requires further investigation. Sometimes, equipment maintenance gets overlooked. This can impact performance. Regular checks can aid in identifying these hidden issues. Balancing these indicators can lead to better outcomes in sludge management.