+86 13600513715

+86 13600513715

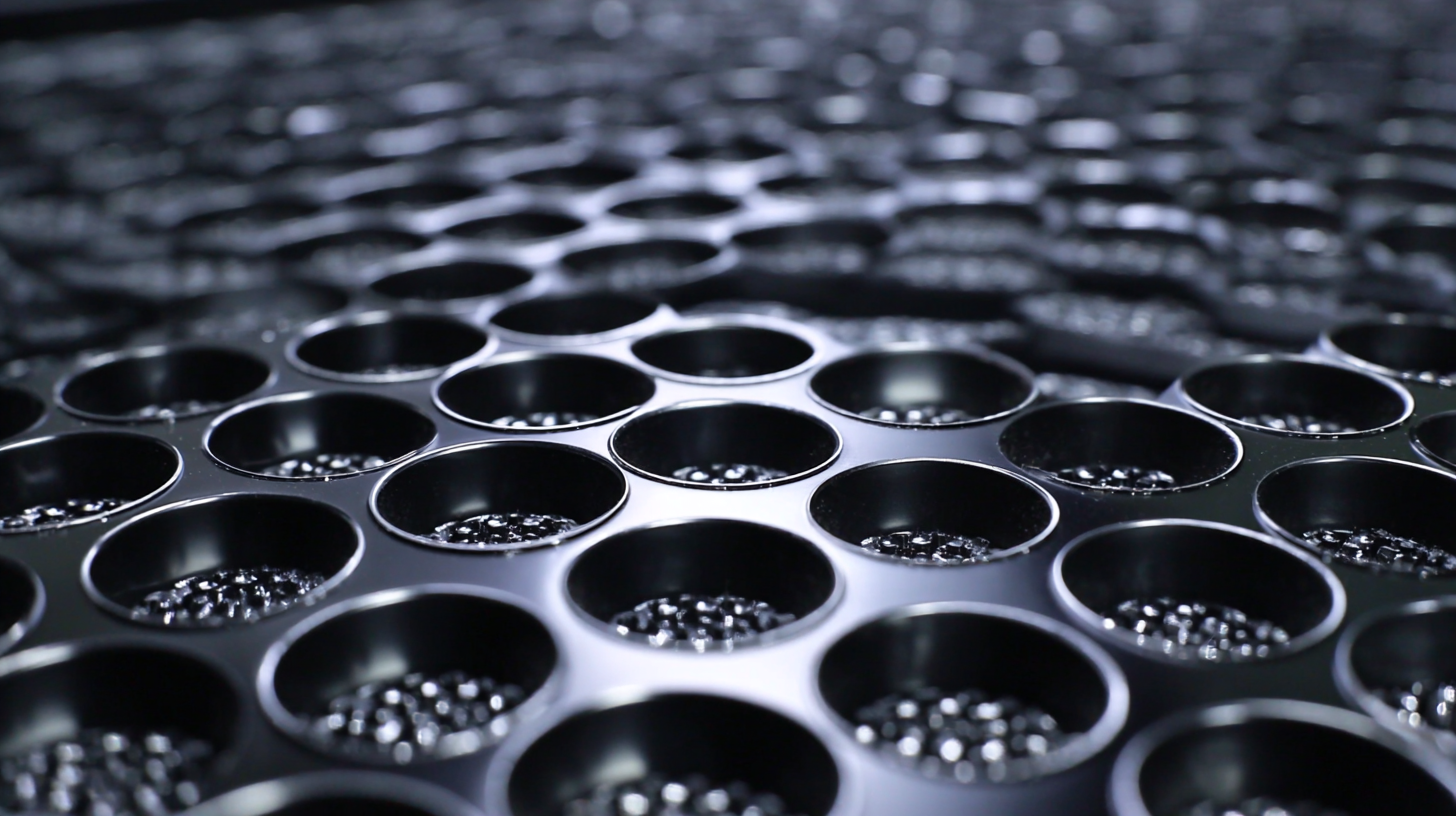

In the rapidly evolving landscape of global manufacturing, China's position as a leading powerhouse is increasingly influenced by innovative technologies and efficient production processes. One such technological advancement at the forefront of this transformation is the Membrane Disc Diffuser. This essential component plays a pivotal role in wastewater treatment and aeration systems, enhancing oxygen transfer efficiency and reducing energy consumption. As industries strive for sustainability and compliance with environmental regulations, understanding how to optimize the use of Membrane Disc Diffusers becomes crucial for manufacturers aiming to improve operational effectiveness while minimizing ecological impact. In this blog, we will explore the mechanisms, benefits, and best practices associated with Membrane Disc Diffusers, offering insights on how to effectively implement these systems to lead in global manufacturing.

China has firmly established itself as a leading global manufacturing power, particularly in specialized sectors like membrane disc diffusers. This dominance is underpinned by a strategic focus on manufacturing capabilities, which has been further enhanced in recent years amid changing global trade dynamics. Despite challenges posed by international tariffs and competition from other nations, China's manufacturing sector continues to thrive. Key developments showcase a robust commitment to innovation and quality, positioning Chinese brands at the forefront of the membrane diffusion technology.

As the global manufacturing landscape shifts, countries like India are making strategic moves to bolster their export competitiveness. However, China's established manufacturing infrastructure, along with its continuous investment in technological advancements, keeps it ahead in key industries. The recent emphasis on enhancing domestic capabilities reflects a long-term vision to not only meet local demands but also strengthen its foothold in global markets. The strategic initiatives taken by the Chinese manufacturing sector echo the nation's commitment to maintaining its role as a powerhouse, particularly in emerging technologies and high-demand products like membrane disc diffusers.

As China positions itself as a global leader in manufacturing, the production of membrane disc diffusers is undergoing significant technological transformation. According to a recent report by MarketsandMarkets, the global membrane diffuser market is expected to reach $2.5 billion by 2025, with a compound annual growth rate (CAGR) of 6.2% from 2020. This surge is largely attributed to advancements in materials and manufacturing techniques, which allow for higher efficiency and durability in wastewater treatment systems.

Key technological advancements are anticipated to enhance the performance of membrane disc diffusers, leading to increased oxygen transfer efficiency and reduced operational costs. For instance, the incorporation of advanced polymer materials not only improves the lifespan of membranes but also enhances their resistance to fouling, a critical issue in wastewater applications. Additionally, smart manufacturing technologies, such as automation and real-time monitoring, will play a crucial role in optimizing production processes, further strengthening China's manufacturing capabilities in this sector. As these innovations unfold, the global market is likely to witness a shift towards more sustainable and efficient water treatment solutions, with China at the forefront.

Optimizing membrane disc diffusers is crucial for enhancing efficiency and performance in various manufacturing sectors. According to recent industry reports, the implementation of advanced membrane diffuser technologies can increase oxygen transfer efficiency (OTE) by up to 30%, significantly reducing operational costs in wastewater treatment processes. This improvement not only maximizes resource utilization but also supports the sustainability goals of many manufacturing plants in China and beyond.

To achieve these benefits, manufacturers should focus on routine maintenance and the selection of high-quality diffuser materials. Regularly checking for blockages and ensuring adequate air supply can further improve performance. For instance, using materials such as EPDM or silicone can help extend the lifespan of diffusers while maintaining optimal functionality.

Tip: Consider conducting performance audits to identify inefficiencies in your current systems. This data-driven approach can reveal opportunities for upgrading your setups, such as transitioning to fine-bubble diffusers, which offer better aeration and lower energy consumption. Additionally, training staff on best practices for operating and maintaining diffuser systems contributes to long-term efficiency gains.

The environmental applications of membrane disc diffusers are experiencing significant advancements, particularly in the context of China’s growing manufacturing power. With a projected growth rate of 5.6% in China’s wastewater treatment market by 2025, membrane disc diffusers are becoming essential components for enhancing aeration efficiency (IBISWorld, 2023). These systems not only improve oxygen transfer rates but also contribute to reduced energy consumption, ultimately promoting sustainable practices within the industry.

Tip: When selecting membrane disc diffusers, consider not only their aeration efficiency but also their material durability to ensure long-term performance in harsh environments.

As we look to the future, membrane disc diffusers are anticipated to play a crucial role in integrating smart technology into environmental management. Reports predict that smart aeration control systems will lead to a 20% increase in operational efficiency by 2030, reducing energy costs and improving overall process management. This shift towards automation and smart technology will be pivotal in addressing the growing environmental challenges and enhancing the performance of wastewater treatment facilities.

Tip: Stay updated on technological innovations and choose diffusers that can be easily integrated with smart control systems to future-proof your operations.

To maintain a competitive edge in the global manufacturing arena, China's diffuser manufacturing sector must adopt strategic approaches that emphasize innovation, quality, and sustainability. One way to achieve this is by investing in advanced technologies that streamline production processes and enhance product performance. For instance, implementing smart manufacturing techniques, such as automation and Internet of Things (IoT) solutions, can significantly improve efficiency and responsiveness to market demands.

**Tip: Focus on Research and Development**

Investing in R&D not only enhances product features but also fosters a culture of innovation. By regularly updating designs based on market feedback, manufacturers can align their products with customer expectations and environmental standards, ensuring long-term success.

Moreover, forming strategic partnerships with global suppliers and clients can bolster China's position in the diffuser market. Collaborations that emphasize shared knowledge and resources can lead to the development of high-performing membrane disc diffusers tailored to various applications worldwide.

**Tip: Emphasize Quality Control**

Instituting rigorous quality control measures throughout the production process ensures that products consistently meet international standards. This commitment to quality not only builds trust with customers but also positions China as a leader in reliable diffuser manufacturing.

| Dimension | Value |

|---|---|

| Total Production Capacity (Units/year) | 1,500,000 |

| Export Percentage (%) | 70% |

| R&D Investment (Million USD) | 50 |

| Number of Patents Filed | 120 |

| Market Share in Asia (%) | 60% |

| Average Production Lead Time (Days) | 30 |

| Environmental Compliance Rate (%) | 95% |