+86 13600513715

+86 13600513715

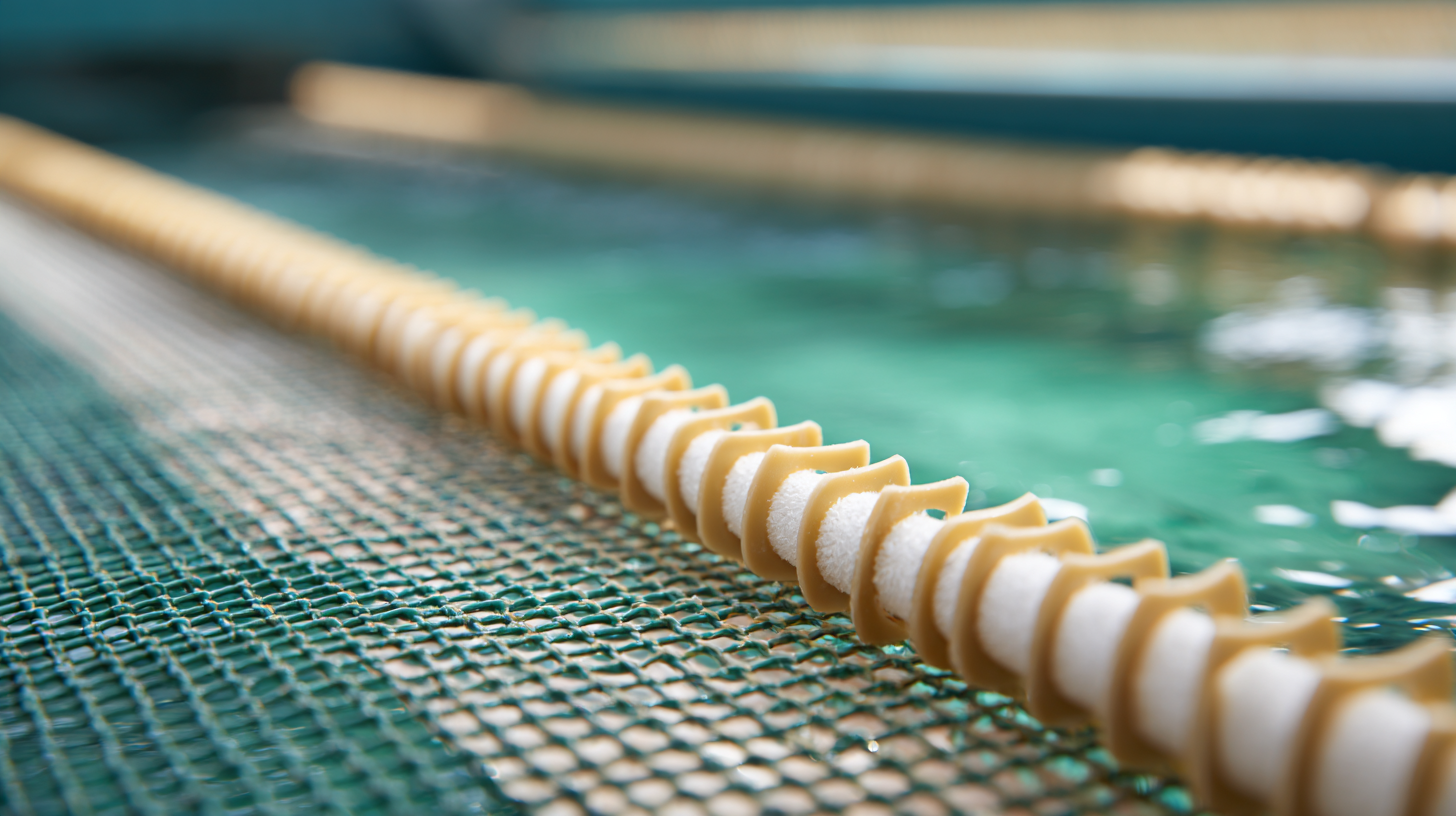

In the realm of wastewater treatment, the continuous pursuit of innovation has led to the emergence of advanced filtration technologies. Among these, the Mbbr Filter stands out as a game-changing solution, offering enhanced efficiency and reliability for various industrial applications. As a leading manufacturer based in China, we pride ourselves on providing the best Mbbr Filter designed for global export. Our commitment to quality and cutting-edge engineering ensures that our filters meet international standards, catering to diverse needs across the globe. In this blog, we will explore the remarkable features of our Mbbr filters, real-world applications, and the reasons why they are considered the best choice for effective wastewater management. Join us as we delve into the principles behind MBBR technology and showcase its transformative impact on environmental sustainability.

The increasing global focus on sustainable practices has led to a surge in demand for advanced wastewater treatment solutions, with MBBR (Moving Bed Biofilm Reactor) filters emerging as one of the leading technologies. These innovative filters offer efficient biological treatment processes that significantly reduce the environmental impact of wastewater. The growing population and industrial expansion, particularly in developing nations, have further accelerated the need for effective filtration systems, driving the market for MBBR filters.

MBBR technology boasts several advantages over traditional methods, including a smaller footprint and greater resilience to fluctuations in wastewater quality. By utilizing biodegradable media, these filters enhance the growth of microorganisms that break down pollutants, resulting in cleaner effluent. As industries recognize the importance of regulatory compliance and the need for resource recovery, MBBR filters are becoming an integral part of modern wastewater treatment strategies, underscoring their importance in achieving both environmental and economic goals.

The MBBR (Moving Bed Biofilm Reactor) technology has emerged as a game-changer in wastewater treatment, offering significant advantages over traditional processes. One of the most compelling benefits is its superior efficiency in removing organic matter and nutrients. According to a report by the Water Environment Federation, MBBR systems can achieve a 30% to 50% reduction in biochemical oxygen demand (BOD) when compared to conventional activated sludge methods, making it a better choice for industrial applications requiring stringent effluent standards.

Moreover, MBBR systems boast a smaller physical footprint, allowing for more flexible installations in constrained spaces. The technology employs biofilm carriers that enhance the biological process, resulting in better treatment performance even at lower retention times. A study published in the Journal of Environmental Management highlights that MBBR can reduce total nitrogen levels by up to 70%, addressing one of the critical issues in water quality management today. This capability not only assists in meeting regulatory reports but also contributes to sustainable water practices, vital for industries aiming to enhance their environmental stewardship while maintaining operational efficiency.

| Feature | MBBR Technology | Traditional Treatment Methods |

|---|---|---|

| Space Efficiency | High | Low |

| Operational Cost | Lower | Higher |

| Maintenance Requirements | Minimal | Significant |

| Adaptability to Load Changes | High | Low |

| Effluent Quality | Consistent | Variable |

| Sludge Production | Lower | Higher |

| BOD Removal Efficiency | High | Moderate |

When it comes to wastewater treatment, the efficiency of MBBR (Moving Bed Biofilm Reactor) filters is a crucial factor for manufacturers and environmental engineers. Understanding performance metrics such as the Specific Biomass Yield (Y), the removal rates of Biological Oxygen Demand (BOD), and the overall treatment efficiency can guide the selection and operational adjustments of MBBR systems. Analyzing these metrics not only indicates a filter’s effectiveness but also helps in optimizing the design and maximizing resource efficiency.

Tip: Regular monitoring of key performance indicators can reveal trends that may indicate system inefficiencies. It is advisable to perform routine checks on influent and effluent quality to ensure the MBBR filter is operating at optimal capacity.

The importance of data in evaluating filter performance cannot be overstated. Statistical analysis can help determine the correlation between influent characteristics and removal efficiencies, allowing for proactive adjustments in operational strategies. By maintaining a robust database of performance metrics, manufacturers can enhance their product offerings while ensuring compliance with global standards for wastewater treatment.

Tip: Consider implementing a predictive maintenance schedule based on data trends, which can help in identifying potential issues before they escalate, ultimately saving time and resources.

China has become a pivotal player in the global filtration market, especially with its innovative MBBR (Moving Bed Biofilm Reactor) filter technology. As projected by market analyses, the global liquid filtration market is set to surge from USD 5.02 billion in 2025 to USD 10.66 billion by 2035, showcasing a robust CAGR of 7.9%. This growth highlights the increasing demand for sustainable and efficient filtration solutions, which aligns with China's strategic focus on environmentally friendly technologies.

Moreover, the PFAS filtration market is expected to reach USD 2.99 billion by 2030. This significant market expansion reflects the mounting concern over water contaminants and the necessity for effective filtration systems. China’s exports of MBBR filters not only contribute to tackling such environmental challenges but also cater to the escalating demand across various regions, driven by both emerging and established markets. As global industries search for reliable filtration solutions, China's role in this sector continues to be indispensable, underscoring its contribution to global advancements in liquid purification and environmental sustainability.

The global demand for MBBR (Moving Bed Biofilm Reactor) filters is on the rise as various markets seek advanced solutions for wastewater treatment. Compliance with regulatory standards is crucial, not only to ensure safety but also to facilitate international trade. Countries are increasingly adopting stringent regulations to safeguard public health and the environment, which manufacturers must navigate carefully to take full advantage of global export opportunities.

In the context of the rapid growth of the advanced water management and filtration equipment market—projected to reach USD 29.5 billion by 2034—manufacturers from China are stepping up to meet these challenges. By aligning their products with international standards, they can better position themselves in competitive markets. This alignment not only assures customers about the efficacy and safety of MBBR filters but also enhances the credibility of Chinese manufacturers on the global stage. Adhering to regulatory compliance ultimately leads to innovation and improvement in product development, ensuring long-term sustainability and success in the international filtration equipment market.