+86 13600513715

+86 13600513715

The demand for efficient water treatment solutions has surged in recent years, primarily driven by the growing need for clean water in both industrial and municipal settings. According to a report by the World Health Organization, around 2 billion people globally lack access to safely managed drinking water, highlighting the urgency for effective water purification technologies. Among the various techniques available, Pp Tube Settlers have emerged as a revolutionary approach to enhance sedimentation processes in water treatment plants.

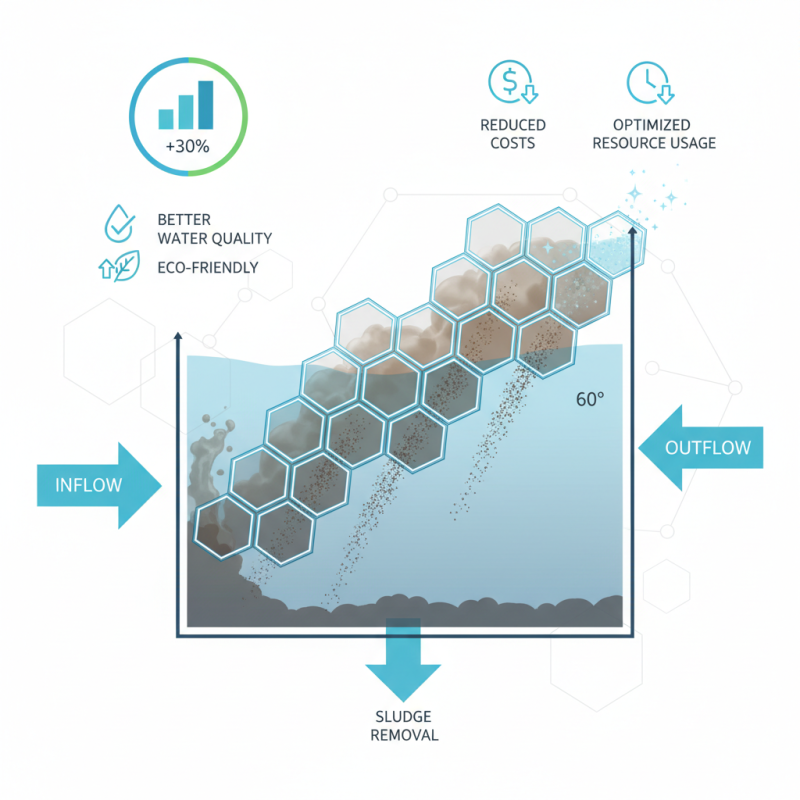

Pp Tube Settlers are designed to maximize the surface area for sedimentation without requiring additional space, thus increasing the overall efficiency of the treatment process. Research indicates that using Pp Tube Settlers can improve sedimentation rates by up to 30%, significantly reducing the operational costs associated with traditional settling basins. By streamlining the concentration of suspended solids in water, these innovative systems not only contribute to better water quality but also optimize resource usage in treatment facilities.

Furthermore, with a growing focus on sustainable practices and environmental protection, implementing Pp Tube Settlers aligns with the industry's shift toward more efficient, eco-friendly water treatment technologies. As agencies and municipalities strive to meet regulatory standards while managing limited resources, understanding the benefits of utilizing Pp Tube Settlers becomes essential for enhancing water treatment efficiency.

PP tube settlers are an innovative solution designed to enhance the efficiency of water treatment processes. These modular systems, composed of polypropylene tubes, utilize gravity to facilitate the settling of suspended solids in water treatment applications. According to a 2021 report by the American Water Works Association, the implementation of tube settlers can improve sedimentation rates by up to 30%, significantly reducing the footprint of treatment facilities while increasing water quality.

The fundamental principle behind PP tube settlers lies in their ability to create a larger surface area for sedimentation compared to traditional settling tanks. The inclined tubes promote laminar flow, which allows particles to settle more effectively. This leads to clearer effluent and a reduction in the need for chemical coagulants. Research indicates that tube settlers can achieve a turbidity reduction of 50% or more, making them an ideal choice for both municipal and industrial water treatment systems.

Tips for optimizing the use of PP tube settlers include ensuring proper installation angles and maintaining consistent flow rates to prevent turbulence that can disrupt settling. Regular maintenance and cleaning of the systems also play a crucial role in maintaining their effectiveness. Moreover, consider integrating complementary technologies such as flocculation and filtration to further enhance overall treatment efficiency.

PP tube settlers are increasingly being recognized for their advantages in enhancing water treatment efficiency. One of the primary benefits of using PP tube settlers is their ability to significantly increase the settling surface area in a compact footprint. This design allows for the effective removal of suspended solids from water, resulting in a clearer and cleaner effluent. By optimizing the settling process, the use of tube settlers leads to improved hydraulic and organic loading rates, making them an indispensable component in modern water treatment facilities.

Another key advantage of PP tube settlers is their durability and resistance to various environmental conditions. Made from high-quality polypropylene, these settlers are not only lightweight but also resistant to corrosion and clogging, ensuring a long service life with minimal maintenance requirements. This robustness contributes to cost-effectiveness over time as plants can avoid frequent replacements or repairs. Furthermore, their ease of installation and adaptability to different systems make them a versatile solution for professionals seeking to enhance water treatment processes while maintaining operational efficiency.

PP Tube Settlers have emerged as a crucial component in a variety of water treatment systems, enhancing sedimentation processes essential for effective water purification. These settlers utilize a series of inclined tubes that create surface area for sedimentation, allowing for the efficient collection of suspended solids. Research indicates that systems incorporating PP Tube Settlers can achieve sedimentation rates up to 20% higher compared to traditional settling methods, significantly improving overall water treatment efficiency. This increase in efficiency is particularly beneficial in municipal wastewater treatment plants, where the removal of particulates is critical for meeting discharge regulations.

Furthermore, the versatility of PP Tube Settlers allows them to be integrated into a range of water treatment settings, from industrial sites to recreational water facilities. Studies by various environmental engineering firms have shown that employing tube settlers can substantially decrease the footprint of sedimentation basins, leading to space-saving designs that do not compromise treatment capabilities. Additionally, the reduced sedimentation time can enhance operational efficiency, as it leads to lower energy consumption and decreased chemical usage, aligning with the industry's move towards more sustainable practices. This adaptability and efficiency make PP Tube Settlers a favored choice in the ongoing quest for optimizing water treatment processes.

The implementation of Pp tube settlers in water treatment processes has shown significant improvements in overall efficiency. According to a report by the American Water Works Association, the use of tube settlers can enhance sedimentation rates by up to 30%. This substantial increase in efficiency allows treatment facilities to reduce their operational costs and improve water quality by ensuring more effective removal of suspended solids.

Performance metrics further highlight the advantages of tube settlers in the water treatment realm. A recent study indicated that plants utilizing tube settlers experienced a reduction in chemical coagulant usage by approximately 20% due to the improved settling characteristics of the treated water. This not only contributes to cost savings but also lessens the environmental impact associated with chemical use in water purification processes. Additionally, the overall turbidity levels in treated water can decrease dramatically, often falling below 1 NTU (Nephelometric Turbidity Units), which is critical for meeting drinking water standards and ensuring public health safety.

| Parameter | Before Tube Settler Use | After Tube Settler Use | Efficiency Gain (%) |

|---|---|---|---|

| Settling Rate (m/h) | 0.5 | 1.2 | 140% |

| Clear Water Production (m³/h) | 20 | 35 | 75% |

| Chemical Usage (kg/m³) | 0.3 | 0.15 | 50% |

| Total Suspended Solids (TSS) (mg/L) | 300 | 50 | 83.33% |

| Operational Cost (USD/hour) | 150 | 100 | 33.33% |

When it comes to enhancing the efficiency of water treatment facilities, the installation and maintenance of PP tube settlers are crucial components that cannot be overlooked. According to a study published by the American Water Works Association, the integration of tube settlers can increase sedimentation efficiency by up to 50%, significantly reducing the overall footprint of treatment systems. These systems function by providing a large surface area for sedimentation while minimizing the water’s flow path, effectively removing suspended solids and improving overall water quality.

Best practices for installing PP tube settlers involve careful consideration of factors such as optimal angle and spacing. The recommended angle typically ranges between 60 and 70 degrees, as this allows for enhanced flow dynamics, which promotes effective settling without causing turbulence. Additionally, maintaining a consistent water level is essential; fluctuations can lead to reduced efficiency and possible operational issues. Regular inspections are vital to ensure that the tube settlers remain free of debris and biofouling. Research from the Water Environment Federation indicates that routine maintenance can extend the lifespan of tube settlers and maintain efficiency levels, with systems showing a 30% increase in performance when properly maintained over time. Adopting these practices not only ensures compliance with regulatory standards but also optimizes water treatment operations for better environmental outcomes.