+86 13600513715

+86 13600513715

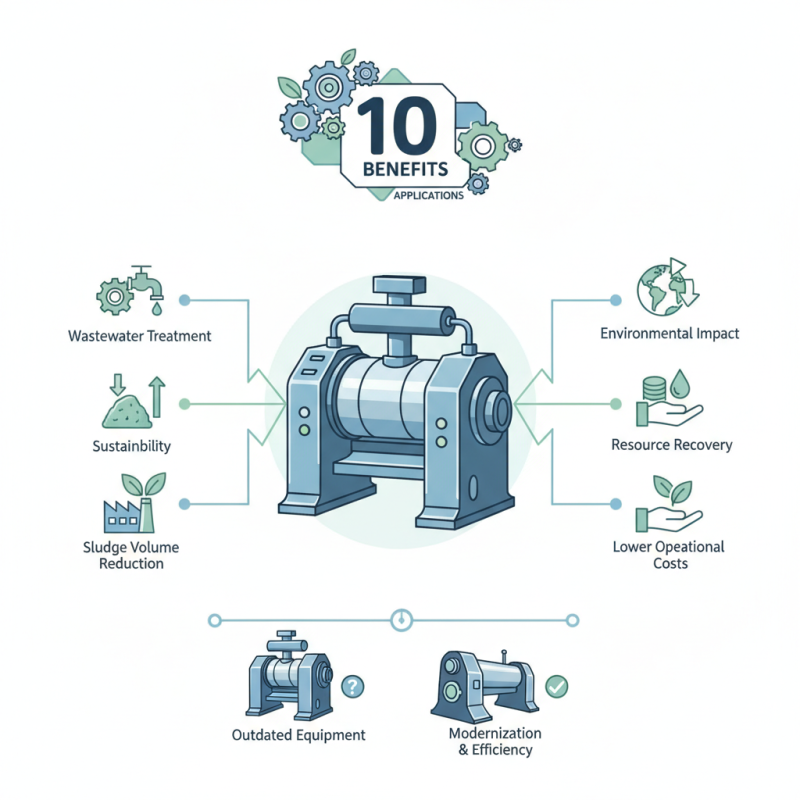

The importance of Sludge Press Machines in wastewater treatment cannot be overstated. According to a recent report by the Water Environment Federation, wastewater treatment facilities face increased pressure to enhance efficiency and sustainability. These machines play a critical role in reducing sludge volume and improving resource recovery.

Expert John Smith, a renowned figure in wastewater technology, highlights, “Investing in advanced Sludge Press Machines can significantly lower operational costs.” This statement reflects the ongoing trend towards more efficient waste management solutions. The shift to dewatering technologies is not just beneficial but necessary in a world increasingly focused on environmental impact.

However, the industry is also facing challenges. Many facilities still rely on outdated equipment, which could lead to inefficiencies. As technology advances, staying ahead is crucial. The right Sludge Press Machine can transform a facility's operations, but the commitment to modernization must be prioritized. The stakes are high, and reflection on current practices is essential for success.

Sludge press machines play a crucial role in waste management. They efficiently dewater sludge, reducing its volume and weight. This makes transportation easier and less expensive. The machines operate by applying pressure to the sludge, forcing out excess water. It is a straightforward yet effective process. Many industries rely on these machines, especially in wastewater treatment.

Understanding their functionality is essential. Sludge press machines use various mechanisms, such as filter presses and screw presses. Each type has unique advantages depending on the application. Some machines may struggle with high solid content, which can lead to challenges. Proper selection can minimize these issues. Regular maintenance is also vital; neglect can cause wear and tear.

Furthermore, sludge disposal is an ongoing concern. Some industries find it challenging to manage byproducts effectively. Innovation in sludge processing is needed. Machines that optimize dewatering can significantly reduce environmental impacts. As industries grow, refining these machines is necessary. The balance between efficiency and sustainability remains crucial.

Sludge press machines play a vital role in modern waste management. They effectively reduce waste volume, which is crucial for reducing landfill usage. According to the Environmental Protection Agency (EPA), about 9.5 billion tons of waste were generated in the U.S. alone in 2019. A significant portion of that is sludge. By using efficient sludge press technology, facilities can minimize this output and maximize recycling efforts.

These machines help in extracting water from sludge, leading to a drier end product. This not only reduces transportation costs but also decreases the energy needed for disposal. Reports indicate that facilities using sludge press machines can achieve up to 90% solid separation efficiency. However, some plants still lag in adopting this technology. The capital investment and ongoing maintenance can seem daunting, but the long-term savings often outweigh initial hurdles.

The reduction in hazardous materials is another key benefit. Sludge press technology can aid in removing harmful substances from waste streams, adhering to stringent environmental regulations. Data from industry sources show that with proper treatment, facilities can see a 50% increase in compliance with environmental standards. Still, many of these machines require skilled operators to maintain optimal performance. There's a constant need for training and awareness in facilities relying on outdated processes.

Sludge press machines play a critical role in various industries, providing efficient waste management solutions. In wastewater treatment, these machines significantly reduce the volume of sludge. According to industry studies, up to 80% volume reduction can be achieved. This efficiency translates into lower transportation and disposal costs. Many municipalities and industries benefit from this technology every day.

In the food processing sector, sludge press machines help manage organic waste. They aid in recycling resources like oils and fats. The reduction in waste not only cuts costs but also boosts sustainability efforts. A report from the Food Waste Reduction Alliance highlights that food processing waste can constitute up to 35% of total waste. Sludge press machines can contribute to lowering that figure.

However, there are challenges. Operators sometimes face issues like clogging and maintenance requirements. These problems can lead to inefficiencies. It's crucial for operators to monitor performance regularly. Overlooking these factors can undermine the benefits of sludge press machines. Balancing efficiency with proper maintenance is essential for maximizing their potential across various applications.

Sludge press machines offer significant advantages over traditional dewatering methods. Their efficiency in removing water is unparalleled. This process not only reduces waste volume but also minimizes operational costs. Moreover, they can handle varying types of sludge effectively. In contrast, methods like centrifugation often require more energy and maintenance. These differences can affect long-term sustainability.

However, the choice between a sludge press machine and other methods depends on specific applications. For instance, some facilities may find belt filter presses more suited for their needs. They can be easier to operate but may lack the same water extraction efficiency. Additionally, the space requirements differ significantly. Sludge presses tend to have a smaller footprint than centrifuges, making them ideal for facilities with limited space.

It's also crucial to consider the initial investment. Sludge presses may have higher upfront costs but can offer savings over time. Still, organizations must assess their unique requirements and budget constraints. This reflection can lead to better waste management solutions. Overall, each method has its strengths and weaknesses. Evaluating these factors is essential for making an informed decision.

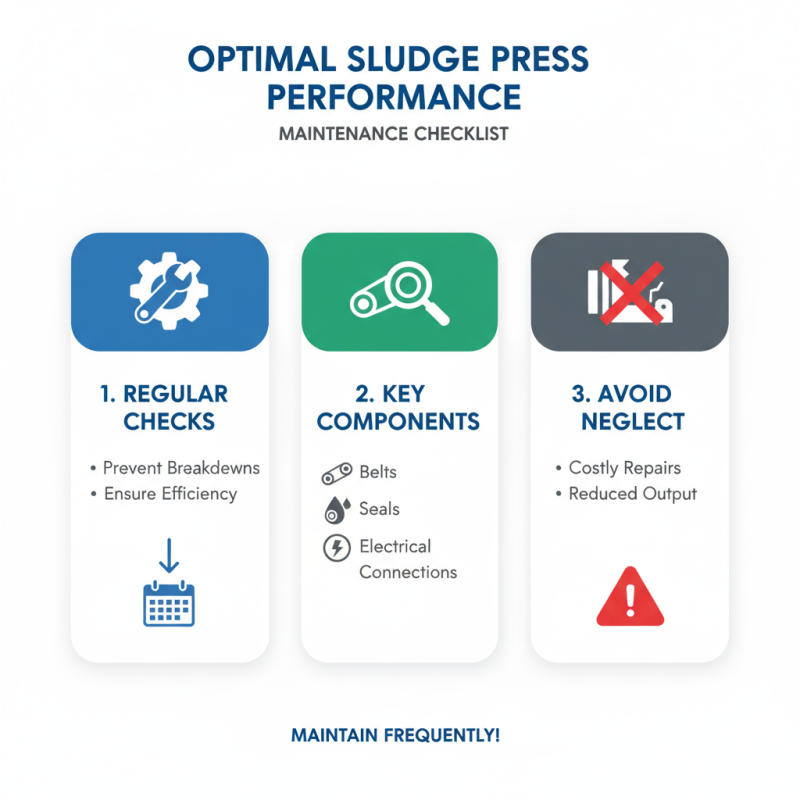

Maintaining sludge press machines is crucial for optimal performance. Regular maintenance checks can prevent costly breakdowns. It’s essential to inspect belts, seals, and electrical connections frequently. Neglecting these areas can lead to inefficiencies and unexpected repairs.

Tips: Regularly schedule routine check-ups. This can save time and money. Observing any unusual noises can also signal issues early.

Efficiency hinges on proper lubrication. Each component should be greased according to the manual. Too much or too little can affect performance negatively. Monitoring temperatures is also vital. If equipment runs too hot, it may indicate a problem.

Tips: Keep a log of maintenance activities. Documenting issues provides insight over time. Consider training staff to spot potential problems. This proactive approach reduces risks and enhances efficiency.