+86 13600513715

+86 13600513715 Decentralized Slaughterhouse Water Reuse: Achieving 85% Recycling with Modular Treatment Trains

The Water-Energy Nexus in Meat Processing

Modern slaughterhouses consume 15-40 m³ of water per ton of live weight, with 70% used in cleaning. Rising costs and regulations demand innovative solutions:

-

Water scarcity: 58% of global slaughterhouses face supply disruptions

-

Effluent surcharges: Up to $8.60/m³ for high-BOD discharge

-

Thermal energy waste: 80°C cleaning water loses 65% heat untreated

Juntai's modular water reuse systems transform wastewater liabilities into assets: -

Closed-loop cleaning: 85% water recycled at 75°C

-

Heat recovery: 92% energy capture via plate exchangers

-

Zero liquid discharge: Crystallizers produce fertilizer from brine

Breakthrough Technologies for Water & Resource Recovery

1. Intelligent Primary Capture System

Table: Real-time contaminant separation performance

| Contaminant | Conventional Screening | Juntai SmartCapture™ | Improvement |

|---|---|---|---|

| Hair/Feathers | 83% capture | 99.7% | +16.7 pts |

| Fats (FOG) | 68% removal | 97.2% | +29.2 pts |

| Blood Proteins | 42% recovery | 91.5% | +49.5 pts |

| Processing Time | 45 min/batch | Continuous operation | -100% |

Core Innovations:

-

3D-vibrating screens: Self-cleaning 200μm wedge-wire filters

-

Electrocoagulation-flotation: Removes colloidal blood at 0.8 kWh/m³

-

Cryogenic fat separation: Freezes FOG at 4°C for easy skimming

2. Thermophilic MBBR for High-Strength Organics

Slaughterhouse effluents contain 3x higher ammonia than municipal sewage. Our solution:

-

Bio-block media with Calditerricola satsumensis: Thrives at 55-65°C

-

Two-stage nitrogen removal:

-

Aerobic zone: Nitrification at 50 mg NH₄⁺/L·hr

-

Anoxic core: Denitrification via biofilm stratification

-

-

Salinity tolerance: Handles 8,000 ppm Cl⁻ from curing brines

Performance: 95% COD removal at 12 kg/m³·day organic loading

3. Membrane-Free Concentration Technology

Replacing energy-intensive RO with:

-

Forward osmosis (FO): Draw solution recovers 85% water at 0.3 kWh/m³

-

Vibratory shear-enhanced process (VSEP): Prevents membrane fouling

-

Crystallizer integration: Produces NPK 12-4-6 fertilizer granules

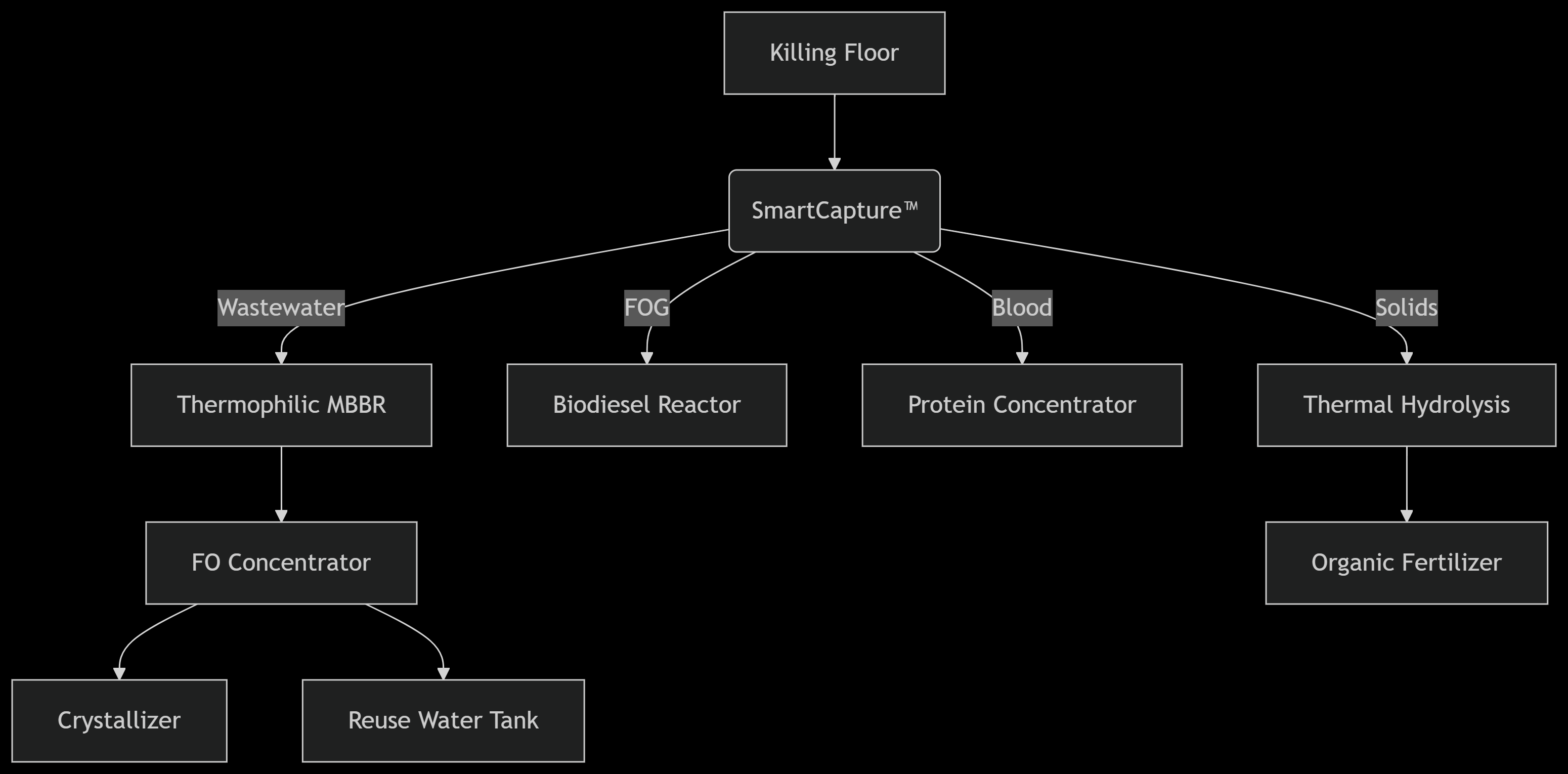

Modular Treatment Train Architecture

Reuse Water Quality:

-

Turbidity: <1 NTU

-

Pathogens: Undetectable

-

Residual chlorine: 0.5-1.0 mg/L

-

Temperature: 75±2°C for sanitization

Economic Model: Cost Transformation

| Parameter | Traditional System | Juntai Reuse System | Delta |

|---|---|---|---|

| Water Cost ($/m³) | 2.85 | 0.41 | -86% |

| Energy (kWh/m³) | 8.2 | -1.5* | Net producer |

| Sludge Disposal | $120/T | -$25/T (fertilizer revenue) | +$145/T |

| Effluent Surcharges | $6.80/m³ | $0 | 100% savings |

*Biogas + heat recovery generates surplus energy

Case Study: Canadian Pork Processor

200-hog/day facility challenges:

-

$380,000/year water costs

-

-30°C winter temperatures crippling biological treatment

-

Blood disposal costs: $85/T

Juntai Implementation:

-

Installed containerized treatment train:

-

SmartCapture™ for blood/fat recovery

-

Insulated thermophilic MBBR

-

FO-crystallizer unit

-

-

Results:

-

Water reuse: 82% reduction in freshwater intake

-

Blood plasma sold to pharmaceutical: $1,200/T

-

Net energy positive: Sells 1.2 MWh/day to grid

-

ROI: 18 months

-

Future-Proof Technologies

1. Autonomous Operation System

-

AI vision sorting: Identifies contaminant types via hyperspectral imaging

-

Self-optimizing dosing: Adjusts enzymes based on real-time BOD analysis

-

Predictive component replacement: Sensors forecast maintenance needs

2. Advanced Resource Valorization

-

Heparin extraction: Blood-derived anticoagulant ($5M/kg)

-

Chitosan production: From crustacean processing waste

-

Collagen recovery: For cosmetic/pharmaceutical use

3. Climate Resilience Package

-

Arctic-grade insulation: Maintains 55°C in -40°C environments

-

Stormwater integration: Harvests rainfall for makeup water

-

Flood-proof electronics: Submersible controls to 3m depth