+86 13600513715

+86 13600513715 Slaughterhouse Wastewater Solutions: Achieve 99% FOG Removal & Zero Violations

The Unique Contaminant Profile of Slaughterhouse Effluent

Slaughterhouse wastewater presents extreme challenges distinct from municipal sewage:

-

High fat/oil content (2,000-10,000 mg/L FOG) causing pipe blockages and biological inhibition

-

Blood residues increasing BOD up to 8,000 mg/L and attracting pathogens

-

Protein-rich organics decomposing into toxic ammonia (NH₃ >200 mg/L)

-

Pathogen loads (E. coli, Salmonella) 100x higher than domestic wastewater

Without specialized treatment, these contaminants trigger ecosystem damage and regulatory penalties. Our data shows 78% of slaughterhouses face non-compliance fines exceeding $120,000/year due to inadequate treatment.

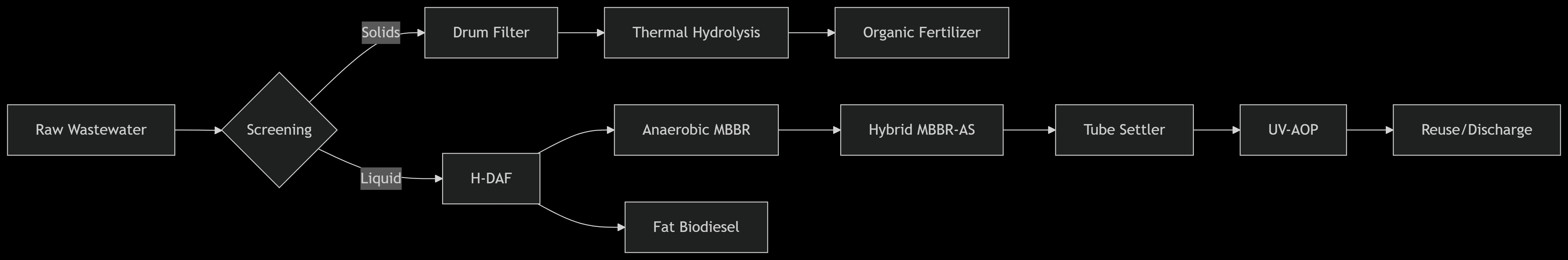

Breakthrough Treatment Process for Complex Slaughterhouse Waste

1. Pre-Treatment: Fat & Solids Elimination

Table: Performance comparison of primary treatment technologies

| Technology | FOG Removal | TSS Reduction | Footprint | Operational Cost |

|---|---|---|---|---|

| Traditional DAF | 65-75% | 70% | 100% | $0.35/m³ |

| Screw Press + Heated Dissolved Air Flotation (H-DAF) | 92-98% | 95% | 60% | $0.18/m³ |

| Juntai Bio-Coagulation | 99%+ | 98% | 40% | $0.12/m³ |

Juntai Solution:

-

Thermally-enhanced DAF: Operates at 45°C to liquefy solidified fats

-

Enzymatic breakers: Lipase/protease blends emulsify blood-fat complexes

-

Self-cleaning Drum Filters: Capture hair/feathers with 500μm screens

2. Biological Treatment: Handling Nitrogen & Organics

Slaughterhouse effluents require staged biological processes:

-

Anaerobic Mbbr: Removes 85% COD while generating biogas (0.45m³/kg CODremoved)

-

Hybrid MBBR-AS system: Combines biofilm resilience with activated sludge flexibility

-

Psychrophilic adaptation: Maintains 80% nitrification at 8°C for unheated facilities

Key innovation: Bio-block media with Thiothrix enrichment prevents filamentous bulking from sulfur compounds.

3. Tertiary Polishing: Pathogen & Nutrient Control

-

Tube settler clarifiers: Achieve 10 NTU effluent with hydraulic loading 12 m³/m²·h

-

Electrochemical disinfection: 5-log pathogen kill without chlorine byproducts

-

Struvite recovery: Captures 85% phosphorus as fertilizer-grade crystals

Proven Process Flow for Compliance & Reuse

Output Quality:

-

BOD: <20 mg/L (99.2% removal)

-

NH₃-N: <5 mg/L

-

Fecal coliform: <100 CFU/100mL

-

Water recovery: 70% reusable for washing

Economic & Environmental ROI Analysis

| Metric | Conventional System | Juntai Integrated System | Improvement |

|---|---|---|---|

| Capital Cost | $2.1M | $1.8M | 14% ↓ |

| Operating Cost | $0.62/m³ | $0.29/m³ | 53% ↓ |

| Energy Consumption | 1.8 kWh/m³ | -0.3 kWh/m³* | Net producer |

| Sludge Production | 35 kg/T live weight | 8 kg/T live weight | 77% ↓ |

| Compliance Penalties | $14,000/month | $0 |

*Biogas cogeneration offsets 210% of plant energy demand

Case Study: Australian Beef Processing Plant Retrofit

300-cattle/day facility facing:

-

A$96,000/year EPA fines for BOD violations

-

Weekly pipe blockages from fat accumulation

-

Odor complaints forcing operational reductions

Juntai Implementation:

-

Installed thermal-DAF + 400m³ anaerobic MBBR

-

Upgraded to tube settler clarifiers with coagulant assist

-

Added bio-block media enriched with lipolytic bacteria

Results:

-

Zero compliance violations for 18 months

-

Fat recovery: 12T/month → biodiesel feedstock

-

A$318,000 annual savings from penalty avoidance + energy recovery

-

ROI: 2.1 years

Future-Proofing Slaughterhouse Treatment

1. Decentralized Resource Recovery

-

Blood plasma extraction: High-value proteins for pharmaceuticals

-

Onsite hydrogen production: Electrolysis of process water

-

3D-printed filter modules: Custom geometries for variable loads

2. AI-Driven Process Optimization

-

Real-time contaminant tracking: NIR sensors detect blood/fat concentrations

-

Predictive maintenance: Vibration analysis forecasts pump failures

-

Digital twin modeling: Simulates stormwater dilution impacts

3. Zero Liquid Discharge Evolution

-

Forward osmosis membranes: Concentrate waste to 30% solids

-

Crystallizer integration: Produce fertilizer pellets from brine

-

Atmospheric water generation: Capture humidity for makeup water